OPS Solutions has installed advances structural repairs according to ISO24817 on several installations on the Norwegian Continental Shelf. In total over 700 successful repairs performed offshore for oil companies, including repairs in class 1, 2, and special repairs.

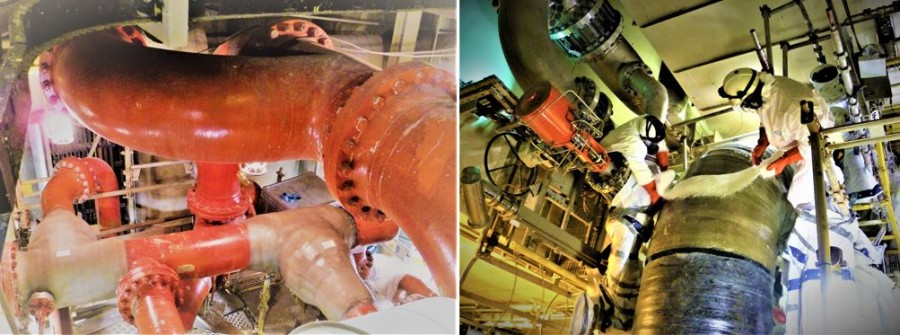

Composite structural repair, wrapping of pipes, tanks and other equipment can be used as both temporary and permanent repairs. This methods can be used when there is limited access to the pipes, it is prohibitively expensive to replace the pipe, or a full replacement is too time consuming.

We are using our own OPS Wrap where each installation of a repair is customized according to its individual requirements. This is made possible by the combination of highly skilled installers and our composite repair designers provide the customer/system owner a unique and flexible repair system with a very fast response time. OPS Solutions is not providing already prepared repair kits.