Corpower ocean Wave Energy Converter

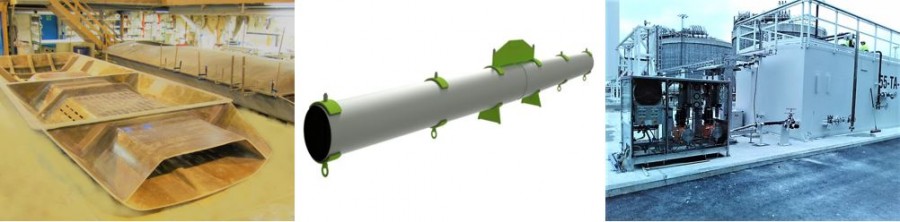

OPS Solutions is developing composite components for clients to enable effective new energy generation (wave, current) or other energy saving technologies.

The common technology platform is maintenance free products, low weight, advantageous buancy in combination of high pressure and subsea application.

OPS Solutions builds on 25 years of experience of designing and manufacturing composite structures for tough conditions and demanding customers.

Competence is the backbone of the operations, from engineering and design to manufacturing and installation, with formal and relevant experience across all parts of the operation.

OPS Solutions provide composite material experts from design to installation.

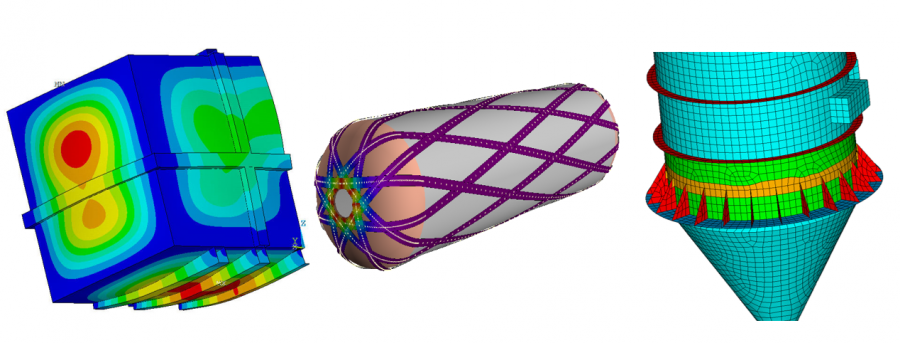

Own R&D resources within composite materials ranging from MSc to PhD level and significant experience on design and Finite Element calculations of composite structures.

Capability to undertake various advanced structural finite element analyses (by means of Ansys and Inventor Pro) and design (by means of Inventor 3D and Auto Cad).

OPS engineering department can provide:

All of the OPS pressure vessels are manufactured by using filament winding process, an advanced stable process providing excellent quality and process control. OPS workshop and procedures for the pressure vessel manufacturing have been surveyed by DNV-GL as a part of DNV product certification process. OPS Solutions has an advanced 5 axis filament machine for production of composite pressure vessels. The type IV composite pressure vessels reduce the weight with more than 50% compared to steel and reduce the need for maintenance compare to conventional pressure vessels.

OPS pressure vessels have a new liner technology based on improved fire resistance and low permeability through the liner thickness. This technology can be used for diameters up to 2.5m, manufactured by OPS large filament winding machine.

The pressure vessels can be manufactured with or without a thermoplastic inner liner depending on the mechanical/physical and chemical loading.

OPS Solutions has developed own flexible liner technology that is combined with the filament winding process providing excellent dual laminate properties. By using this liner the OPS composite pressure vessels can be used for many types of media (acids and alcalic solutions) in combination with pressure and high temperatures.

Our pressure vessels are developed inhouse by our engineers and OPS Solutions can provide advanced type approved composite products delivered according to strict design rules including 3rd party verification on design and production by several Notified Bodies (ABS, DNV GL and BV). The composite vessels can be approved according to PED, ISO 11119-3, EN 12245 and ADR depending on the application.

OPS Solutions has an extensive experience with both one off products and series of pressure vessels both exposed to chemicals and pressure.

OPS Solutions has developed concepts for different segments within advanced composite pressure vessels:

OPS Solutions has developed a PED category IV composite vessel design for water technology. The concept can be used for water filtering or water injection systems where the process design pressure is up to 20 bars.

The pressure vessels are designed according to DNV-GL C501. The design ensures low weight compared to steel and low maintenance cost for the composite structure.

The pressure vessel prototypes have been subjected to full static and dynamic fatigue testing according to DNV-GL C501.

OPS Solutions has developed a high pressure vessel concept for general storage applications. The vessel is a general purpose type IV pressure vessel with a thermoplastic liner and a conductive GRE structural laminate.

Testing of pressure vessels:

To obtain a DNV(or similar) product certificate the static and dynamic fatigue tests must be performed. OPS Solutions has all equipment necessary to perform the tests and has established a test site for burst testing.

OPS Solutions deliver complete solutions and systems design based on composite materials. OPS engineers are specialists in design, construction and manufacturing using polymer composite materials.

OPS Solutions delivers special designed complex shaped structures within all our business areas.

The combination of material science and a thorough understanding of chemical interaction with the composite material provides strong and chemical resistant product for unique products.

OPS Solutions has an excellent track record for developing composites special products/prototypes together with clients within different fields of applications.

OPS Solutions applies modern design tools like Inventor® and Ansys® during product development together with clients.

Reidar Anderssen

General Manager / Vice President

T: +47 48 06 50 22

ra@opsas.no

Kjetil Sevenius

R&D Manager

T: +47 93 45 11 81

ks@opsas.no

OPS Solutions AS | Organization number: 992 810 874

OPS Composite Solutions AS | Organization number: 991 437 541

Buråsen 20 | 4636 Kristiansand | Norway | T: +47 97 71 74 00 | post@opsas.no

Privacy

© 2020 OPS AS | All rights reserved

Design: Tress Design | CMS: Monoform