OPS Solutions has developed utility power poles for use in arctic climate for both regional (132KV) and distribution segment (<60KV). The OPS Utility Power Poles have been developed and thoroughly tested according to REN blad (governing standards for power poles/grid in Norway). Composite poles are strong, flexible, predictable and provide long service life. Creosote, being a carcinogen, will most probably be banned by the EU from 2022, meaning conventional wood poles will be phased out over the coming years.

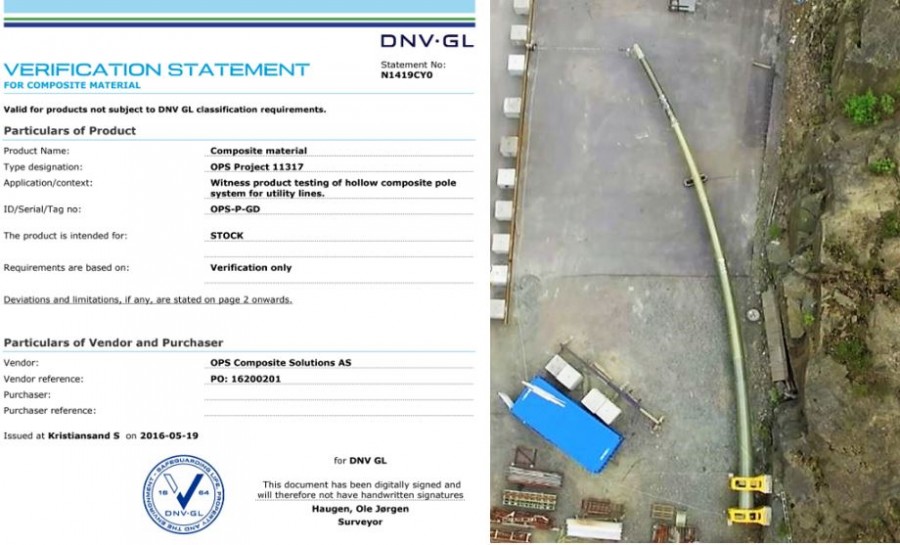

Our Utility Power Poles are developed by OPS engineers and approved according to governing design rules including 3rd party verification on design and production by Notified Body (DNVGL).

OPS Solutions has also built up test facility for performing large scale bending testing of up to 30 m poles. OPS Solutions has used advanced numerical FEM buckling simulations to develop the poles and the OPS production philosophy regarding quality and traceability from offshore related products has successfully been transferred to power pole production.

OPS Solutions has built up a new library in PLSPOLE/PLSCAD for all OPS utility power poles modules and pole combinations. OPS Solutions provides expert support for the consultants and Grid owners designing new composite power lines.

OPS Solutions has a very flexible production and the production method is easy to scale up to meet short term delivery requirements. OPS Solutions has utility power poles production located in Norway with short distance to the customers and the possibility to manufacture special poles for high load line points.

OPS Solutions has also a patent pending foundation method for the composite power poles for environmentally friendly installation without the need of blasting.

OPS utility power poles can be remotely monitored by OPS Solutions using sensors.

Reidar Anderssen

General Manager / Vice President

T: +47 48 06 50 22

ra@opsas.no

Kjetil Sevenius

R&D Manager

T: +47 93 45 11 81

ks@opsas.no